Emstunnel

HEIGHT: 8.40 m

WIDTH: 27.50 m

TOTAL IMMERSED LENGTH: 639.5 m

DEPTH AT BOTTOM OF STRUCTURE:19 m below MWL

ENVIRONMENTAL CONDITIONS: Mean tide 2.61 m. Mean current 1m/s. Siltation was a problem

FABRICATION METHOD: The elements were built together in a graving dock adjacent to the tunnel trench. Each element was cast in five 25.5 m segments. To prevent cracks, a cooling system was installed. The segments were post-tensioned for placing, after which the post-tensioning bars were cut.

WIDTH: 27.50 m

TOTAL IMMERSED LENGTH: 639.5 m

DEPTH AT BOTTOM OF STRUCTURE:19 m below MWL

ENVIRONMENTAL CONDITIONS: Mean tide 2.61 m. Mean current 1m/s. Siltation was a problem

FABRICATION METHOD: The elements were built together in a graving dock adjacent to the tunnel trench. Each element was cast in five 25.5 m segments. To prevent cracks, a cooling system was installed. The segments were post-tensioned for placing, after which the post-tensioning bars were cut.

Leer,

Germany

Niedersachsisches Landesamt für Strassenbau through agent: Autobahn Neubau Amt of Oldenburg

Joint venture consisting of: Hollandsche Beton- en Waterbouw (HBW), and the local firms Brewaba (German company owned by HBW), Beton- und Tiefbau Mast Hermann Hein, Martin Oetken, Bauunternehmen Hein

IMS Ingenieurgesellschaft mbH, Hamburg

127.5m

639.5m

19m

Project construction

1989-04-30

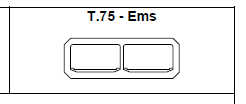

5

Two tubes; two lanes plus one emergency lane per tube.

8.40m

27.50m

An unexpectedly high rate of sedimentation (approx 15 cm per tide change) filled the trench

immediately after each element was placed. Special equipment was developed to remove the

siltation under the element a few meters in front of the sandjetting operation.

immediately after each element was placed. Special equipment was developed to remove the

siltation under the element a few meters in front of the sandjetting operation.

The elements were built together in a graving dock adjacent to

the tunnel trench. Each element was cast in five 25.5 m

segments. To prevent cracks, a cooling system was installed.

The segments were post-tensioned for placing, after which the

post-tensioning bars were cut.

the tunnel trench. Each element was cast in five 25.5 m

segments. To prevent cracks, a cooling system was installed.

The segments were post-tensioned for placing, after which the

post-tensioning bars were cut.

After all of the elements were

finished, the dock was flooded

and the dike was removed

using a dredge. Before floating

each element, two pontoons

equipped with lowering and

mooring winches were floated

over the elements and

connected to them. After

deballasting, the element

floated with the pontoons on

top.

finished, the dock was flooded

and the dike was removed

using a dredge. Before floating

each element, two pontoons

equipped with lowering and

mooring winches were floated

over the elements and

connected to them. After

deballasting, the element

floated with the pontoons on

top.

Mean tide 2.61 m. Mean current 1m/s. Siltation was a problem

After winching the element to its location, it was placed by ballasting and lowering. It was

temporarily supported by primary and secondary supports.

temporarily supported by primary and secondary supports.

Gina/Omega system. Elements

divided into 25 segments.

divided into 25 segments.

Impermeable reinforced concrete with a bituminous layer over the roof, protected with 0.2 m of

protection concrete.

protection concrete.

Jetted-sand foundation. Special equipment was developed to clean the area under the tunnel just

in front of the sandjetting operation

in front of the sandjetting operation

Approximately 1 m of stone cover on reinforced concrete slab on roof the elements

Reinforced

1.02 for placement