Vltava Tunnel

HEIGHT: 6.48m

WIDTH: 6.48m

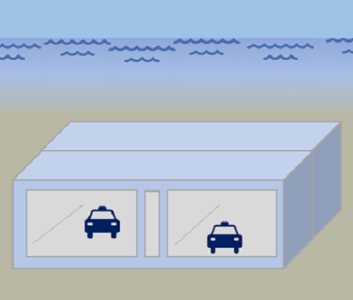

TOTAL IMMERSED LENGTH: 336m (Two elements placed side by side 168m + 168m)

DEPTH AT BOTTOM OF STRUCTURE: Water depth above tunnel is 6-7m

ENVIRONMENTAL CONDITIONS:

The width of the river is 180m at the crossing point

FABRICATION METHOD:

On-line casting within cofferdam on line of tunnel

WIDTH: 6.48m

TOTAL IMMERSED LENGTH: 336m (Two elements placed side by side 168m + 168m)

DEPTH AT BOTTOM OF STRUCTURE: Water depth above tunnel is 6-7m

ENVIRONMENTAL CONDITIONS:

The width of the river is 180m at the crossing point

FABRICATION METHOD:

On-line casting within cofferdam on line of tunnel

Prague,

Czech Republic

Dopravní podnik hl. m. Prahy a. s.

Metrostav a.s. with Zakladani a.s., TGB Metrostav.a.s., PERI & VSL

Metroprojekt a.s

2 elements @ 168m Formed by 14 no 12m long segments connected by working joints. Reinforcement is going through the joints.

336m

6-7m

Project construction

2002-04-30

2, placed side by side

Single track in each element, for twin track metro line

6.48m

6.48m

Elements were cast on line and slid into position on a horizontal curve within narrow cofferdams

On-line casting within cofferdam on line of tunnel

Outfitting within cofferdam

The width of the river is 180m at the crossing point

The tunnel elements were negatively buoyant. A pontoon was used to support front of the

elements. Hydraulic telescopic sliding shoes were used at the secondary end. Elements were

pulled though cofferdam with winches. Sliding shoes were guided by rails.

elements. Hydraulic telescopic sliding shoes were used at the secondary end. Elements were

pulled though cofferdam with winches. Sliding shoes were guided by rails.

Along 168 m no expansion

joints. At the ends expansion

joints used stainless steel

elements and rubber sealing

joints. At the ends expansion

joints used stainless steel

elements and rubber sealing

Watertight concrete with no external membrane. Full section casting in a single pour avoided

cracks.

cracks.

Grout bags

0.5 to 3m cover with sand, gravel and

stone

stone

C30/37 ENV 206-1

Heating used at the working joints

Reinforcement using mild steel only

Heating used at the working joints

Reinforcement using mild steel only

Temporary overweight during sliding: Element 1 70t Element 2 57t Permanent loading by cover and bottom slab is anchored into the subbase using micropiles.