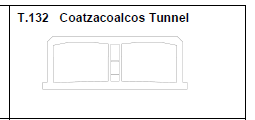

Túnel sumergido de Coatzacoalcos

HEIGHT: Maximum 9.6m Minimum 9.2 m

WIDTH: 25.1 m

TOTAL IMMERSED LENGTH: 698 m

DEPTH AT BOTTOM OF STRUCTURE: 30.5 m below sea level

ENVIRONMENTAL CONDITIONS:

At the tunnel location water levels are influenced by the tide in the Gulf of Mexico. River

conditions allow only for immersion in the period February - May

The Rio Coatzacoalcos has high discharge in the rain season (September – November) and

also transports a lot of siltation.

The port of Coatzacoalcos is important for the region because of the petroleum industry and is

visited by many ships.

FABRICATION METHOD:

Element cast in segments with permanent prestressing to

enable transport and immersion and to coop with seismic

impact.

Casting basin on eastern embankment.

WIDTH: 25.1 m

TOTAL IMMERSED LENGTH: 698 m

DEPTH AT BOTTOM OF STRUCTURE: 30.5 m below sea level

ENVIRONMENTAL CONDITIONS:

At the tunnel location water levels are influenced by the tide in the Gulf of Mexico. River

conditions allow only for immersion in the period February - May

The Rio Coatzacoalcos has high discharge in the rain season (September – November) and

also transports a lot of siltation.

The port of Coatzacoalcos is important for the region because of the petroleum industry and is

visited by many ships.

FABRICATION METHOD:

Element cast in segments with permanent prestressing to

enable transport and immersion and to coop with seismic

impact.

Casting basin on eastern embankment.

Rio Coatzacoalcos, state of Veracruz,,

Mexico

(Project promotor:) State of Veracruz and Banobras

CTC: Joint venture of FCC from Spain and Impulsa and OPC from Mexico

Tunnel Engineering Consultants (TEC)

4 @ 138 m 1 @ 146m

698m

30.5m

Project construction

5

Two tubes with two lanes each and a service gallery in between

Maximum 9.6m Minimum 9.2 m

25.1m

Variable and soft soil conditions

Moderate to severe seismic conditions, seismic zone B (PGA = 0.32g), which require special

immersion and segment joint design:

- Immersion joint: special large GINA profile to accommodate seismic movements in

combination with passive tendons

- Segment joint: permanent prestressing (0.5-2.0 N/mm2) in combination with crack inducers

and injection hoses to repair potential cracks due to seismic events

Due to permanent prestressing in the segment joints the element will behave as a monolithic

tunnel structure, resulting in heavy shear keys in the immersion joints.

The longitudinal reinforcement is continued over the segment joints using smaller bar diameters.

Internal Gina gasket in last element (at 8 meter from element face) constructed in casting basin.

Moderate to severe seismic conditions, seismic zone B (PGA = 0.32g), which require special

immersion and segment joint design:

- Immersion joint: special large GINA profile to accommodate seismic movements in

combination with passive tendons

- Segment joint: permanent prestressing (0.5-2.0 N/mm2) in combination with crack inducers

and injection hoses to repair potential cracks due to seismic events

Due to permanent prestressing in the segment joints the element will behave as a monolithic

tunnel structure, resulting in heavy shear keys in the immersion joints.

The longitudinal reinforcement is continued over the segment joints using smaller bar diameters.

Internal Gina gasket in last element (at 8 meter from element face) constructed in casting basin.

Element cast in segments with permanent prestressing to

enable transport and immersion and to coop with seismic

impact.

Casting basin on eastern embankment.

enable transport and immersion and to coop with seismic

impact.

Casting basin on eastern embankment.

Elements are fitted out in the

casting basin, where a

temporary mooring location is

created.

casting basin, where a

temporary mooring location is

created.

At the tunnel location water levels are influenced by the tide in the Gulf of Mexico. River

conditions allow only for immersion in the period February - May

The Rio Coatzacoalcos has high discharge in the rain season (September – November) and

also transports a lot of siltation.

The port of Coatzacoalcos is important for the region because of the petroleum industry and is

visited by many ships.

conditions allow only for immersion in the period February - May

The Rio Coatzacoalcos has high discharge in the rain season (September – November) and

also transports a lot of siltation.

The port of Coatzacoalcos is important for the region because of the petroleum industry and is

visited by many ships.

For placement of the elements winch pontoons, land winches and 2 catamarans are used. For

positioning a GPS survey system is installed on the access shaft and survey tower. All

immersion equipment for this project is containerized.

positioning a GPS survey system is installed on the access shaft and survey tower. All

immersion equipment for this project is containerized.

Special large Gina Seal to deal

with seismic impact and

Standard Omega seal.

Dywidag bars over immersion

joints to prevent opening of

joints during an earthquake.

with seismic impact and

Standard Omega seal.

Dywidag bars over immersion

joints to prevent opening of

joints during an earthquake.

Watertight concrete using artificial cooling and a sprayed structural waterproofing system on

walls and roof.

walls and roof.

Gravel bed (thickness 0.6-0.75 m), placed using scrading method with fall pipes

1.5m: gravel, filter layer and rock fill

C30/37; reinforcement steel grade 42,

permanent longitudinal prestressing

EN 1992-1, prestressed in longitudinal

direction (after immersion prestress is not cut).

permanent longitudinal prestressing

EN 1992-1, prestressed in longitudinal

direction (after immersion prestress is not cut).

temporary condition1,025/ permanent condition 1,05