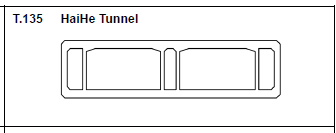

HaiHe Tunnel

HEIGHT: 9.65 m

WIDTH: 36.6 m

TOTAL IMMERSED LENGTH: 255 m

DEPTH AT BOTTOM OF STRUCTURE: 25 m approx.

ENVIRONMENTAL CONDITIONS:

Silty clay with moderate erosion environment.

Water level and current can be adjusted by upstream and downstream water gates.

FABRICATION METHOD:

All elements built in a casting basin at the south C&C

tunnel site.

WIDTH: 36.6 m

TOTAL IMMERSED LENGTH: 255 m

DEPTH AT BOTTOM OF STRUCTURE: 25 m approx.

ENVIRONMENTAL CONDITIONS:

Silty clay with moderate erosion environment.

Water level and current can be adjusted by upstream and downstream water gates.

FABRICATION METHOD:

All elements built in a casting basin at the south C&C

tunnel site.

Tianjin,

China

Tianjin Haihe Downstream Development CO., LTD.

China Railway 18th Bureau Group CO., LTD.

Shanghai Tunnel Engineering & Rail Transit Design and Research Institute

85m

255m

25m

Project construction

3

Two main tubes each with three lanes for vehicles. Three services gallery.

9.65m

36.6m

First immersed tube tunnel in North China for roadway use.

Flexible joint designed for seismic load, uneven settlement and thermal stresses.

R=1500 curve elements.

Flexible joint designed for seismic load, uneven settlement and thermal stresses.

R=1500 curve elements.

All elements built in a casting basin at the south C&C

tunnel site.

tunnel site.

Silty clay with moderate erosion environment.

Water level and current can be adjusted by upstream and downstream water gates.

Water level and current can be adjusted by upstream and downstream water gates.

Placed by pontoons.

GINA / OMEGA Type. Post-tensioned cables across joint.

Vertical and horizontal shear keys provided at walls and

slabs.

Vertical and horizontal shear keys provided at walls and

slabs.

Galvanized steel plate was adopted for base slab waterproofing; For the side walls and

top slab, polyurea spraying membrane were used.

top slab, polyurea spraying membrane were used.

Grouting foundation with screeded gravel

1.5 m of backfill.