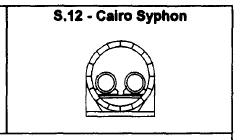

Syphon under the Nile

HEIGHT: 4.35 m

WIDTH: 3.75 m

TOTAL IMMERSED LENGTH: 464 m

DEPTH AT BOTI'OM OF STRUCTURE: 20.9 m at flood

FABRICATION METHOD:

Elements were vertically cast, then turned, lined up, and

posttensioned. Special runners picked them up. These

runners were used to launch the element sideways into

the water.

ENVIRONMENTAL CONDITIONS:

Schedule had to fit low water during January and flood conditions during August

through October. Launching could not be done during low water. Dredging and placing

could not be accomplished during flood conditions. Slipways were constructed at site.

WIDTH: 3.75 m

TOTAL IMMERSED LENGTH: 464 m

DEPTH AT BOTI'OM OF STRUCTURE: 20.9 m at flood

FABRICATION METHOD:

Elements were vertically cast, then turned, lined up, and

posttensioned. Special runners picked them up. These

runners were used to launch the element sideways into

the water.

ENVIRONMENTAL CONDITIONS:

Schedule had to fit low water during January and flood conditions during August

through October. Launching could not be done during low water. Dredging and placing

could not be accomplished during flood conditions. Slipways were constructed at site.

Cairo,

Egypt

Municipality of Cairo

Hochtief, AG Volume

Hochtief, AG

40.5-56.8m

464m

20.9m

Project construction

1964-04-30

9

One tube; carries two 1.20 m dia sewer force mains.

4.35m

3.75m

Vertically cast segmental construction. Interior pipes install~l prior to installing end

bulkheads. 5 m segments weighed about 40 t. Up to 11 segments were posttensioned

into a tunnel element.

bulkheads. 5 m segments weighed about 40 t. Up to 11 segments were posttensioned

into a tunnel element.

Elements were vertically cast, then turned, lined up, and

posttensioned. Special runners picked them up. These

runners were used to launch the element sideways into

the water.

posttensioned. Special runners picked them up. These

runners were used to launch the element sideways into

the water.

Internal force mains were

installed prior to installation

of the dam plates.

installed prior to installation

of the dam plates.

Schedule had to fit low water during January and flood conditions during August

through October. Launching could not be done during low water. Dredging and placing

could not be accomplished during flood conditions. Slipways were constructed at site.

through October. Launching could not be done during low water. Dredging and placing

could not be accomplished during flood conditions. Slipways were constructed at site.

Catamaran pontoon assembly at the one end and a jack-up platform at the other, both

equipped with lowering winches were used. Ballasting was done by partly filling the

sewer lines installed in the elements. Alignment was done by using survey columns.

equipped with lowering winches were used. Ballasting was done by partly filling the

sewer lines installed in the elements. Alignment was done by using survey columns.

Tremie concrete joint. Interior

welded steel liner

plates welded in place after

elements were accessed

from inside.

welded steel liner

plates welded in place after

elements were accessed

from inside.

Vertically cast using high density concrete. Steel joint closures.

Saddle blocks were cast in place against the bottom of the trench using tremie concrete.

Forms were attached to the elements prior to placement and sand bags were

used to seal around them. Used floating batch plant.

Forms were attached to the elements prior to placement and sand bags were

used to seal around them. Used floating batch plant.

2 m of quarry stone over one meter of sand backfill above tunnel.