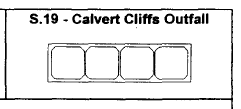

Calvert Cliffs Outfall Conduit

HEIGHT: 4.41 m

TOTAL IMMERSED LENGTH: 305 m

WIDTH: 16.76 m

DEPTH AT BOTTOM OF STRUCTURE: 6.6 m

ENVIRONMENTAL CONDITIONS:

Heavy marine traffic throughout tow route. Shallow depth exposure to wave action.

FABRICATION METHOD:

Cast in an excavated basin in Chesapeake, Virginia and

towed 200 km to the site.

TOTAL IMMERSED LENGTH: 305 m

WIDTH: 16.76 m

DEPTH AT BOTTOM OF STRUCTURE: 6.6 m

ENVIRONMENTAL CONDITIONS:

Heavy marine traffic throughout tow route. Shallow depth exposure to wave action.

FABRICATION METHOD:

Cast in an excavated basin in Chesapeake, Virginia and

towed 200 km to the site.

Maryland,

United States

Baltimore Gas & Electric Co.

Tidewater Construction Corporation

Bechtel Associates

61m

305m

6.6m

Project construction

1972-04-30

5

four tubes

4.41m

16.76m

Tunnel was constructed from elements which had three removable bulkheads. The

inboard end bulkheads for each separate tube was divided into four sections which

!were light enough to be hooked onto and dragged by cable. The outboard bulkhead on

each tube could be hoisted away as a single piece. The elements were floated into

position and ballasted internally to a negative buoyancy of 100 tons. These were then

lowered to the previously dredged and screeded bottom and two jacks were used to

tighten the new element against the previous one with a simple dumbbell gasket in

between. The new element was then flooded and divers progressively removed the

i outboard bulkhead, the middle bulkhead, and finally the four pieces of the inboard

bulkhead. Model tests of the handling characteristics of the element were undertaken

at the U. S. Corps of Engineers laboratory in Vicksburg, Mississippi. These tests indicated

that wave action caused a significant increase on the loading of the lowering

falls during placement.

inboard end bulkheads for each separate tube was divided into four sections which

!were light enough to be hooked onto and dragged by cable. The outboard bulkhead on

each tube could be hoisted away as a single piece. The elements were floated into

position and ballasted internally to a negative buoyancy of 100 tons. These were then

lowered to the previously dredged and screeded bottom and two jacks were used to

tighten the new element against the previous one with a simple dumbbell gasket in

between. The new element was then flooded and divers progressively removed the

i outboard bulkhead, the middle bulkhead, and finally the four pieces of the inboard

bulkhead. Model tests of the handling characteristics of the element were undertaken

at the U. S. Corps of Engineers laboratory in Vicksburg, Mississippi. These tests indicated

that wave action caused a significant increase on the loading of the lowering

falls during placement.

Cast in an excavated basin in Chesapeake, Virginia and

towed 200 km to the site.

towed 200 km to the site.

In casting basin.

Heavy marine traffic throughout tow route. Shallow depth exposure to wave action.

Temporary guide beams. Water ballast to 100 ton negative buoyancy. Sections were

jacked together. Element was then completely flooded and bulkheads were removed

by divers as described above.

jacked together. Element was then completely flooded and bulkheads were removed

by divers as described above.

:Dumbbell shaped neoprene

gasket. Compressed by jacking

only. Ultimate watertightness

not critical because of nature of

tunnel.

gasket. Compressed by jacking

only. Ultimate watertightness

not critical because of nature of

tunnel.

Not applicable.

Screeded bed using temporary pile supported frame.

There was no protective cover over the top of the element. The element was not

placed in a trench but just sat on the screeded bed.

placed in a trench but just sat on the screeded bed.