Amsterdam-Rhine Canal Water Transport Tunnel

HEIGHT: 2.85 m

WIDTH: 8.89 m

DEPTH AT BOTTOM OF STRUCTURE: 10 m approx.

TOTAL IMMERSED LENGTH: 132 m

ENVIRONMENTAL CONDITIONS:

Constructed across an active canal.

FABRICATION METHOD:

Match cast segments. A special measuring post was

used to measure the length of the next segment to be

cast. The segments were joined with epoxy resin and

temporarily prestressed. Finally 32, 55 mm cables and 6

BBRV cables were used for final post-tensioning. Element

was assembled in a vacant canal lock.

WIDTH: 8.89 m

DEPTH AT BOTTOM OF STRUCTURE: 10 m approx.

TOTAL IMMERSED LENGTH: 132 m

ENVIRONMENTAL CONDITIONS:

Constructed across an active canal.

FABRICATION METHOD:

Match cast segments. A special measuring post was

used to measure the length of the next segment to be

cast. The segments were joined with epoxy resin and

temporarily prestressed. Finally 32, 55 mm cables and 6

BBRV cables were used for final post-tensioning. Element

was assembled in a vacant canal lock.

Amsterdam,

Netherlands

Rijkswaterstaat

N.V. Nestum II (Consortium) consisting of:. N.V. Nederlandsche Beton Maatschappij, Christiani & Nielsen NV, Van Hattum & Blankevoort, Hollandsche Beton Ma=schappij NV, NV Internationale Gewapend Beton Bouw, NV Nederlandsche Aannemingsmaatschappij, NV Amst

132m

132m

10m

Project construction

1973-04-30

1

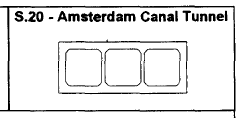

Three tubes interconnecting the Amsterdam Rhine Canal with the Vaartse Rijn which crosses it.

2.85m

8.89m

Entire tunnel fabricated as a single immersed element from 44, 3 m prefabricated

segments post-tensioned together.

segments post-tensioned together.

Match cast segments. A special measuring post was

used to measure the length of the next segment to be

cast. The segments were joined with epoxy resin and

temporarily prestressed. Finally 32, 55 mm cables and 6

BBRV cables were used for final post-tensioning. Element

was assembled in a vacant canal lock.

used to measure the length of the next segment to be

cast. The segments were joined with epoxy resin and

temporarily prestressed. Finally 32, 55 mm cables and 6

BBRV cables were used for final post-tensioning. Element

was assembled in a vacant canal lock.

Fitted with bollards, hooks

for winching, watertight

bulkheads and ballast

tanks.

for winching, watertight

bulkheads and ballast

tanks.

Constructed across an active canal.

Placed using two floating cranes. Ballasting with concrete slabs on roof of tunnel.

Screeded gravel.

Sand fill to bottom of canal