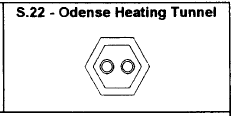

District Heating Tunnel

HEIGHT: 2.67 m

WIDTH: 3.08 m

TOTAL IMMERSED LENGTH: 90 m

DEPTH AT BOTTOM OF STRUCTURE: 9.1 m

ENVIRONMENTAL CONDITIONS: Tunnel site on protected Odense Canal

FABRICATION METHOD:

Precasting of 5 m long segments in vertical position.

Assembling of segments and post-tensioning in nearby

purpose-built drydock

WIDTH: 3.08 m

TOTAL IMMERSED LENGTH: 90 m

DEPTH AT BOTTOM OF STRUCTURE: 9.1 m

ENVIRONMENTAL CONDITIONS: Tunnel site on protected Odense Canal

FABRICATION METHOD:

Precasting of 5 m long segments in vertical position.

Assembling of segments and post-tensioning in nearby

purpose-built drydock

Odense,

Denmark

Odense Municipality Corporation

Dansk Entreprenerselskab Christiani & Nielsen NS

90m

90m

9.1m

Project construction

1974-04-30

1

One tube

2.67m

3.08m

Precasting of 5 m long segments in vertical position.

Assembling of segments and post-tensioning in nearby

purpose-built drydock

Assembling of segments and post-tensioning in nearby

purpose-built drydock

At tunnel site

Tunnel site on protected Odense Canal

Two pontoon rigs were Used to sink the tunnel element. Heating mains were utilized

as ballast chambers.

as ballast chambers.

Injected cement-mortar

paste with additives in

segments joints

paste with additives in

segments joints

No waterproofing membrane

Jetted sand foundation was installed using patented Christiani & Nielsen method

1 m of sand fill