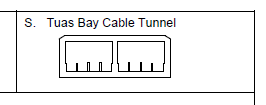

Tuas Bay Cable Tunnel

HEIGHT: 4.425m

WIDTH: 11.79m

TOTAL IMMERSED LENGTH: 2.1km

FABRICATION METHOD:

4m segments constructed on quay, rotated, and lifted into

position for prestessing to form monolithic elements.

Assmbled and stressed on purpose built ship lift which

subsequently lowered elements into water

WIDTH: 11.79m

TOTAL IMMERSED LENGTH: 2.1km

FABRICATION METHOD:

4m segments constructed on quay, rotated, and lifted into

position for prestessing to form monolithic elements.

Assmbled and stressed on purpose built ship lift which

subsequently lowered elements into water

Singapore,

Singapore

PUB

Obayashi

Parsons Brinkerhoff

100m

2.1km

Project construction

1998-07-11

17No. straight, 4 curved

Twin tube with cable troughs running below vehicle running surface in each tube

4.425m

11.79m

The tunnel has one 90 degree bend and one 45 degree bend, achieved by using tapered

segments to form curved elements.

The tunnel carries 400kV and 230kV power cables and has a water pipe cooling system to

remove heat.

segments to form curved elements.

The tunnel carries 400kV and 230kV power cables and has a water pipe cooling system to

remove heat.

4m segments constructed on quay, rotated, and lifted into

position for prestessing to form monolithic elements.

Assmbled and stressed on purpose built ship lift which

subsequently lowered elements into water

position for prestessing to form monolithic elements.

Assmbled and stressed on purpose built ship lift which

subsequently lowered elements into water

Initially on ship lift, then final

outfitting when held by

sheerlegs

outfitting when held by

sheerlegs

Elements were negatively buoyant and supported by floatation tanks for transportation. 2no

400T sheerleg cranes used for lowering.

400T sheerleg cranes used for lowering.

Gina & omega gaskets

Watertight concrete achieved by single pour segments to avoid joints and risk of cracking.

Glued joints between segments.

Glued joints between segments.

Pumped sand foundation through pipe in central dividing wall. Single line of injection points due

to narrow width.

to narrow width.

1.25m deep rock above tunnel, 2m

deep rock protection to sides.

deep rock protection to sides.

1.05