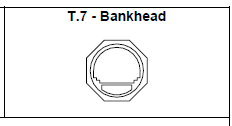

Bankhead Tunnel

TOTAL IMMERSED LENGTH: 610 m

HEIGHT: 10.4

WIDTH: 10.4

DEPTH AT BOTTOM OF STRUCTURE: 25 m

FABRICATION METHOD: In shipyard 1 km away from site. The elements were sidelaunched into river, then placed in shipyard’s drydock for placement of keel concrete (for stability). The element was then towed to the outfitting yard near the site.

SITE CONDITIONS: river

HEIGHT: 10.4

WIDTH: 10.4

DEPTH AT BOTTOM OF STRUCTURE: 25 m

FABRICATION METHOD: In shipyard 1 km away from site. The elements were sidelaunched into river, then placed in shipyard’s drydock for placement of keel concrete (for stability). The element was then towed to the outfitting yard near the site.

SITE CONDITIONS: river

Mobile, Alabama, U.S.A.,

United States

City of Mobile revenue bond issue

Arundel Corporation of Baltimore and the Alabama Drydock and Shipbuilding Company.

Messrs Wilberding and Palmer Inc (of Washington D.C)

5-90.8m 2-78.0m

610m

25m

Project construction

1940-03-31

7

One tube; two lanes; one each way

10.4m

10.4m

Placed from pile-supported frames. Foundation material was placed with element held

in position from frames. Elements were placed a few inches high to accommodate

settlement.

in position from frames. Elements were placed a few inches high to accommodate

settlement.

In shipyard 1 km away from site. The elements were sidelaunched

into river, then placed in shipyard’s drydock for

placement of keel concrete (for stability). The element

was then towed to the outfitting yard near the site.

into river, then placed in shipyard’s drydock for

placement of keel concrete (for stability). The element

was then towed to the outfitting yard near the site.

Concrete was placed from

floating batch plant.

floating batch plant.

Gallows frames supported from H-pile clusters.

Tremie concrete.

Continuous steel shell.

Element was held at grade while sand was placed along the sides with tremie pipes.

A minimum of 3 m of backfill