Maas Tunnel

TOTAL IMMERSED LENGTH: 584 m

DEPTH AT BOTTOM OF STRUCTURE: 22.5 m

HEIGHT: 8.39 m

WIDTH: 24.77 m

FABRICATION METHOD: Existing dock in Heyse Harbor. Roof slab was left off until the element was floating in Waal Harbor. Three cycles of three elements were used.

SITE CONDITIONS: river

DEPTH AT BOTTOM OF STRUCTURE: 22.5 m

HEIGHT: 8.39 m

WIDTH: 24.77 m

FABRICATION METHOD: Existing dock in Heyse Harbor. Roof slab was left off until the element was floating in Waal Harbor. Three cycles of three elements were used.

SITE CONDITIONS: river

Rotterdam,

Netherlands

(under Nieuwe Maas-River)

Gemeente Rotterdam (Municipality of Rotterdam)

N.V. Maastunnel, a joint venture consisting of: Christiani & Nielsen N.V. of the Hague, N.V. Internationale Gewapend Beton Bouw (now member of Royal Bos Kalis Westminster Group), N.V. Nederlandsche Aanneming Mij (now member of Ballast-Nedam Group), M.J. H

Christiani & Nielsen A/S, Copenhagen

61.35m

584m

22.5m

Project construction

1943-04-01

9

Four lanes in two tubes for vehicles. One tube for cyclists and one tube for pedestrians

8.39m

24.77m

Immersed tunnel terminated in ventilation buildings constructed as pneumatic caissons.

Construction spanned the occupation of Holland during Second World War

Construction spanned the occupation of Holland during Second World War

Existing dock in Heyse Harbor. Roof slab was left off until the element was floating in

Waal Harbor. Three cycles of three elements were used.

Waal Harbor. Three cycles of three elements were used.

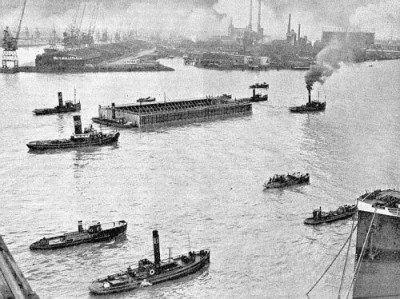

Lowering by means of floating cranes. Pontoons along the sides of the elements were

used to provide positive buoyancy

used to provide positive buoyancy

6 mm steel membrane covered with coating of concrete to inhibit rusting.

Sandjetted foundation. Very first application of Christiani & Nielsen method