Benelux Tunnel

TOTAL IMMERSED LENGTH: 744 m

DEPTH AT BOTTOM OF STRUCTURE: 24 m

HEIGHT: 7.84 m

WIDTH: 23.9 m

ENVIRONMENTAL CONDITIONS: Swift river currents created sedimentation problems in the dredged trench

FABRICATION METHOD: At casting basin constructed for the tunnel. All eight sections were cast at the same time.

DEPTH AT BOTTOM OF STRUCTURE: 24 m

HEIGHT: 7.84 m

WIDTH: 23.9 m

ENVIRONMENTAL CONDITIONS: Swift river currents created sedimentation problems in the dredged trench

FABRICATION METHOD: At casting basin constructed for the tunnel. All eight sections were cast at the same time.

Rotterdam,

Netherlands

Ministry of Public Works; Rijkswaterstaat

N.V. Amsterdamsche Ballast Mij; Christiani & Nielsen N.V.; Internationale Gewapendbeton-Bouw N.S.; Nederlandsche Aanneming Mij, v/h firma H.F. Boersma and N.V. Nederlandsche Beton Maatschappij (N.V. Nestum II)

Locks and Weirs Department of the Rijkswaterstaat

93m

744m

24m

Project construction

1967-04-30

8

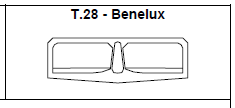

Two tubes; two lanes of traffic in each tube

7.84m

23.9m

Tunnel is completely curved, with all tubes cast as identical curved sections

At casting basin constructed for the tunnel. All eight

sections were cast at the same time.

sections were cast at the same time.

Took place in casting basin.

Swift river currents created sedimentation problems in the dredged trench

Used four pontoons for lowering. A tower for survey was provided at the outboard end of

the tube; a tower for access and control was provided on the inboard end.

the tube; a tower for access and control was provided on the inboard end.

Pulled together using a

hook, the Gina-type gasket

was engaged; conventional

dewatering followed to

make up the joint

hook, the Gina-type gasket

was engaged; conventional

dewatering followed to

make up the joint

Bituminous membrane, protected by reinforced concrete

Used foundation plates supported on layer of gravel for temporary grade adjustment.

Sand was then jetted under tunnel elements, after acceptable conditions were obtained.

Silt skirts were used to protect the area under the elements from being filled with soft silt

scour off the bottom of the river

Sand was then jetted under tunnel elements, after acceptable conditions were obtained.

Silt skirts were used to protect the area under the elements from being filled with soft silt

scour off the bottom of the river