Drecht Tunnel

HEIGHT: 8.08 m

WIDTH: 49.04 m

TOTAL IMMERSED LENGTH: 347 m

DEPTH AT BOTTOM OF STRUCTURE: 15 m

ENVIRONMENTAL CONDITIONS: River currents.

FABRICATION METHOD: At casting yard at Barendrecht (used previously for the Heinenoord and some pipeline tunnels), 12 km from site.

WIDTH: 49.04 m

TOTAL IMMERSED LENGTH: 347 m

DEPTH AT BOTTOM OF STRUCTURE: 15 m

ENVIRONMENTAL CONDITIONS: River currents.

FABRICATION METHOD: At casting yard at Barendrecht (used previously for the Heinenoord and some pipeline tunnels), 12 km from site.

Dordrecht,

Netherlands

Kombinatie Tunnelbouw: Dirk Verstoep BV, Van Hattem en Blankevoort and Koninklijke Nederhorst Bouw BV

Rijkswaterstaat, Directive Sluizen en Stuwen

115m

347m

15m

Project construction

1977-04-30

3

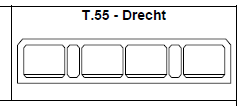

Four tubes; two lanes in each tube

8.08m

49.04m

Widest element ever constructed. Displacement 45,000 MT. Approach structures are of

a very unusual construction, utilizing drained slabs and top-down construction, with

slurry walls carried to clay. Tunnel elements were attached to end structures already in

place - on one end of tunnel, using a Gina joint; and on the other, using a gasketted

plate joint system. Two-lane spans were used to reduce depth of elements. Sand-flow

method was used for second time.

a very unusual construction, utilizing drained slabs and top-down construction, with

slurry walls carried to clay. Tunnel elements were attached to end structures already in

place - on one end of tunnel, using a Gina joint; and on the other, using a gasketted

plate joint system. Two-lane spans were used to reduce depth of elements. Sand-flow

method was used for second time.

At casting yard at Barendrecht (used previously for the

Heinenoord and some pipeline tunnels), 12 km from site.

Heinenoord and some pipeline tunnels), 12 km from site.

River currents.

Model tests were used to determine the number of tugs required to handle the segment.

The tests indicated 5,000 to 6,000 HP; however, 11,000 HP eventually were provided

for safety. Clearances for towing were very restricted, and an elaborate electronic

horizontal control method was implemented to keep elements from running aground.

Element blocked 40% of river at times during towing.

Transverse pontoons with two control/alignment towers were used for placement. Fourpoint

support was used at placement because of the width of the section. Vertical and

horizontal jacks were used for adjustment of alignment.

The tests indicated 5,000 to 6,000 HP; however, 11,000 HP eventually were provided

for safety. Clearances for towing were very restricted, and an elaborate electronic

horizontal control method was implemented to keep elements from running aground.

Element blocked 40% of river at times during towing.

Transverse pontoons with two control/alignment towers were used for placement. Fourpoint

support was used at placement because of the width of the section. Vertical and

horizontal jacks were used for adjustment of alignment.

Gina type joints

Membrane waterproofing was used because of the great width of the tunnel. The

elements were divided into six subsections with temporary prestress, which was cut

after backfilling.

elements were divided into six subsections with temporary prestress, which was cut

after backfilling.

The sand-flow method used on the Vlake tunnel was repeated for this tunnel.

Reinforced